ISO 13849-1:2015 is an essential tool for the design and integration of safety-related control systems in machines. It is applicable to all types of machines, including mobile, stationary and stationary machines with moving parts.

The standard is based on a risk assessment approach, which means that it requires the identification and assessment of hazards and risks associated with machinery and the specification of appropriate safety measures to mitigate these risks. It includes a hierarchy of safety measures, with safety control systems being the highest level in the hierarchy.

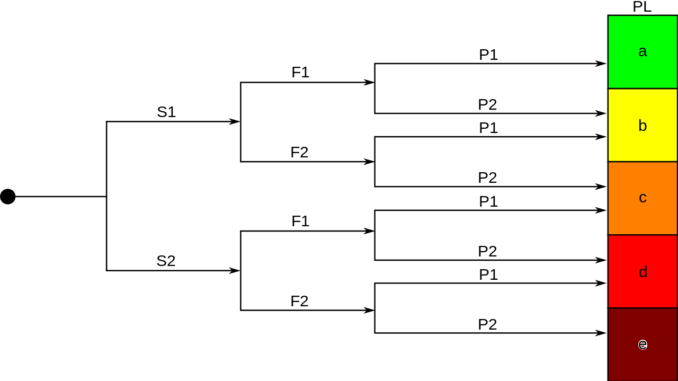

The standard also defines four performance levels (PL) for safety control systems, ranging from PL a (lowest) to PL e (highest). These performance levels are based on the probability of a hazardous failure per hour, with PL a being the lowest and PL e being the highest.

In addition to these performance levels, the standard also includes provisions for assessing the safety integrity level (SIL) of safety control systems. SIL is a measure of the reliability of safety functions and is based on the probability of a dangerous failure per hour. The standard defines four SIL levels (SIL 1, SIL 2, SIL 3, and SIL 4), with SIL 4 being the highest level of reliability.

ISO 13849-1:2015 also includes requirements for the design, installation and maintenance of safety control systems, including hardware, software and the interaction between them. It also includes requirements for the documentation of the safety control system, including a safety plan, a safety manual and a safety report.

In summary, ISO 13849-1:2015 is a valuable tool for ensuring the reliability and effectiveness of safety control systems in machinery. It is essential to ensure the safety and health of workers and others who may be exposed to risks associated with machinery.

The following is a table of performance levels (PL) for safety control systems:

PL “a”: Highest performance level. Safety control devices of this level have a very low probability of failure and are used in situations where the risk of injury or damage is very high.

PL “b”: High performance level. Safety control devices of this level have a low probability of failure and are used in situations where the risk of injury or damage is high.

PL “c”: Medium performance level. Safety control devices at this level have a moderate probability of failure and are used in situations where the risk of injury or damage is moderate.

PL “d”: Low performance level. Safety control devices at this level have a high probability of failure and are used in situations where the risk of injury or damage is low.

PL “e”: Lowest performance level. Safety controls at this level have a very high probability of failure and are used in situations where the risk of injury or damage is very low.

It is important to note that these performance levels are not defined in absolute terms, but rather in terms of the probability of a dangerous failure per hour. Thus, a PL a safety control system may be considered more reliable than a PL b system in a specific application, depending on the risks and safety requirements associated with that application.

Leave a Reply